PRODUCTS

CARBON CAPTURE SYSTEM

Langh Tech’s onboard carbon capture system is based on our long-standing experience of exhaust gas treatment and applies a post-combustion technique.

BALLAST WATER MANAGEMENT SYSTEM

LanghBW Systems introduces a compact and effective UV-based treatment system which combines fine filtration and efficient UV-C treatment. The system has IMO and USCG type approval for treating the sea water only at intake.

SOx SCRUBBER

Langh Tech's SOx scrubber is environmentally friendly as it can be operated continuously in closed loop mode without any time limits or big holding tanks...

Besides the closed loop version the Langh Tech scrubber is also available in an open loop and a hybrid version that combines both models...

The Langh Tech water treatment system can be used to clean the water from both sources; the closed loop SOx scrubber and the EGR system...

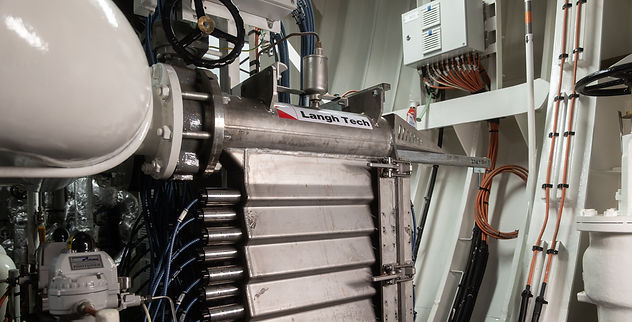

Carbon Capture System

Langh Tech’s OCC system supports customers in their decarbonisation journey by reducing CO2 emissions from ship operation.

Langh Tech’s onboard carbon capture system is based on our long-standing experience of exhaust gas treatment and applies a post-combustion technique.

In short, the ship’s exhaust gases containing CO₂ are directed into a capture unit. CO₂ dissolves into the liquid phase through counter-currently flowing aqueous caustic soda (NaOH) solution. A maximized surface area ensures highest possible carbon capture rates. As a result of several consecutive reactions, CO₂ is chemically bound into a thermodynamically stable product of sodium carbonate (Na₂CO₃).

Langh Tech’s first OCC system has been running successfully in test mode since spring 2024. The pilot plant testing phase has been highly successful, demonstrating momentary peak capture rates of up to 90% of the exhaust gas flow entering the system. Nevertheless, extensive vessel-specific case studies conducted during the testing period indicate that capture rates in the range of approximately 10-50% are technically and economically more feasible under practical operating conditions for many vessel types. Therefore, Langh Tech's OCC system is optimized to capture around 50% of the CO₂ coming into the system, which can be tailored to a specific capture rate by treating only a part of the entire exhaust gas.

Moreover, the solid product of sodium carbonate, which results from the OCC process, can be turned into value. It can easily be marketed as it is widely applied as a key ingredient by various other industries, for example in the manufacturing of glass and detergents. The conventional production of sodium carbonate predominantly relies on extracting ores from the Earth's crust and, therefore applying a low-carbon alternative from Langh Tech's OCC system can contribute to decarbonization of related industries as well.

With Langh Tech’s OCC, there is no need for solvent regeneration or CO₂ compression, which significantly reduces the additional energy consumption onboard as well as the equipment and resources needed to operate the OCC system. In turn, the capture reagent, NaOH, can be produced by electrolysis of sodium chloride using renewable energy. This ensures minimized emissions and sustainability over the whole lifecycle.

The OCC system allows simple operation processes which do not require new specialized equipment. The used reagent is already applied and established in the maritime industry. The system can also be adapted and scaled according to the specific needs of each vessel. This approach ensures a seamless integration of the technology into the existing ship infrastructure, offering a practical solution for a wide range of ship types.

Up to 50% capture rate

Capture product contributing to circularity

Ballast Water Management System

In addition to exhaust gas cleaning systems, Langh Tech has added ballast water management system into its product portfolio.

LanghBW Systems introduces a compact and effective UV-based treatment system which combines fine filtration and efficient UV-C treatment. The system has IMO and USCG type approval for treating the sea water only at intake.

The 20 micron filtration mesh removes all large size organisms from the intake ballast water, and the UV-reactor installed downstream of the filter disinfects the remaining water with high intensity UV-C irradiance. LanghBW systems has a zero hour hold time before discharge in IMO areas and 24 hours in USCG areas. This means that in IMO areas, water treated twice can be discharged instantly without any retention time. During the discharge operation the filter is bypassed and only second UV-dose is applied.

The flow rate of available systems varies from 100 m³/h to 1800 m³/h but even bigger systems can be built whenever needed. The scalability of LanghBW Systems is basing on one reactor design. One UV-reactor is capable of treating 100-300 m³/h of ballast water and the desired flow rate is achieved by installing multiple reactors in parallel. Using only one reactor type simplifies the design and installation work and makes the operation and maintenance easy and straight forward. The reactor design itself provides an effective way for UV-treatment, therefore lowering the system’s power consumption and making the system capable for efficient operation in high turbidity waters with UVT down to 45%.

LanghBW Systems is designed from mariner to mariner. Our valued design goals have been easy and reliable operation, simple user interface, affordable operation costs and effortless maintenance. During the design phase, the crew onboard Langh Ship’s vessels was involved into the development process to ensure the system’s suitability for demanding onboard environment and challenging operating requirements.

Fine filtration + UV-C treatment

Ballast Water Management System for ballasting rates from 100 m³/h to 1800 m³/h

Closed loop scrubber

Langh Tech's SOx scrubber is environmentally friendly as it can be operated continuously in closed loop mode without any time limits or big holding tanks.

The closed loop process utilizes fresh water in addition to suitable alkali, which can be caustic soda or magnesium. No untreated process water is pumped overboard during operation. No dilution, no tricks. Just a unique water treatment process to handle the process water. More than 90% of the process residuals are extracted from the process water flow, which makes the equipment very environmentally friendly.

The scrubber tower design can be either inline or side-inlet type (U-type) and with either single or multiple inlets. The scrubber can be dry running or use a bypass.

The Inline scrubber tower attenuates sound and can replace the silencer. The scrubber tower is always tailor-made to each project and is therefore available in many different sizes from small towers for 1MW engine power up to large towers for 70 MW engine power. Not only can one main engine but also multiple flue gas sources be connected into one inline scrubber with the manifold that collects all the flue gases together and feeds them to scrubber.

The scrubber is equipped with a packing bed which has better performance than using multi-level water sprays only. The packing bed intensifies chemical reactions, thus enabling smaller scrubber size and less water flow through the scrubber. The applied packing bed material is robust and therefore the back pressure - the pressure drop trough the scrubber tower - maintains low.

The scrubber can be equipped either with one or two packing beds. A tower with one packing is ideal for a vessel where vertical space for the scrubber tower is limited, whereas a two packing bed tower is taller but slimmer in diameter, which makes it a perfect solution for vessels where the space inside the funnel or engine casing is limited. It is especially designed for RoPax/RoRo and cruise vessels where every inch matters in the narrow casings.

Scrubber tower design either inline or side-inlet typ (U-type)

Caustic soda or magnesium can be used as a chemical

Open loop and hybrid scrubber

Besides the closed loop version the Langh Tech scrubber is also available in an open loop and a hybrid version that combines both models.

The scrubber tower design can be either inline or side-inlet type (U-type) and with either single or multiple inlets. The scrubber can be dry running or use a bypass.

In open loop mode sea water is utilized as process water. Alkalinity – salinity and carbonates – act as process reactants to reduce sulphur oxides (SOx) to the desired level. This simple in-out process is efficient and easy.

The hybrid scrubber is a combination of best performance and flexibility as this high-end product combines the best sides of the closed loop and open loop modes.

The owner can make the decision which mode is to be used and when. This solution provides technical and environmental efficiency in a handy way.

The scrubber tower design can be either inline or side-inlet type (U-type)

Langh Tech hybrid scrubber can be operated continously in closed loop

Scrubber Water Treatment System

CLOSED LOOP WTS

The Langh Tech Water Treatment System for closed loop scrubber is reliable, efficient and easy-to-use. Water cleaning is based on efficient membrane filtration where additional flocculants are not needed. The system has a sludge dewatering function, and thus the amount of waste left over after the closed loop water treatment process is marginal compared to other wet scrubber solutions.

The Langh Tech solution manages to extract almost all water from the scrubber sludge and the end result is a dry black waste. The highly concentrated dry sludge is unitized in IBC containers or barrels. Waste disposal is effortless and cost-effective.

The system has no operation time limitations and big holding tanks are not needed. The water treatment system is built from compact size equipment modules which facilitates flexible installation of equipment in the engine room.

The modules exist in many different water flow capacities and the required total water cleaning capacity can be achieved by combining suitable modules together.

The unique Langh Tech closed loop water treatment system can also be combined with other manufactures’ scrubbers.

EGR WTS

Langh Tech has expanded its water treatment technology to new areas. The EGR water treatment system is reliable, efficient and easy-to-use and has similar performance and advantages as the SOx scrubber water treatment system.

Langh Tech has been working in close cooperation with MAN Diesel & Turbo (MDT) to develop a water treatment system to be used for cleaning the process water of Exhaust Gas Recirculation (EGR) systems. EGR is a method to reduce NOx emissions to meet Tier III requirements. In the EGR process, approximately one third of the exhaust gas is recycled back into the engine, first removing the particles from the redirected gases with a small scrubber. The process water from exhaust gas washing is continuously cleaned during EGR operation and this is where Langh Tech’s water treatment technology is applied. The Langh Tech water treatment is based on membrane filtration, meaning that the operational costs are kept low and the waste consists only of small amounts of compact dry sludge.

The first test runs of the system were performed in 2015 at the MDT testing facility in Copenhagen, using a small-scale prototype built into a container. The results were good, leading to a continued and deepened cooperation between the companies. The process has been fine-tuned over time, and a MDT approval for the Langh Tech water treatment system to be used in combination with the EGR process was received in 2016. The approval process includes a long-term testing period in cooperation with MDT.

The Langh Tech water treatment system can be used to clean the water from both sources; the closed loop SOx scrubber and the EGR system. The combined water treatment system lowers the initial investment and requires less space on board the vessel versus the independent systems for closed loop and EGR processes.

No need for sludge tanks

Combined water treatment system for SOx scrubber and EGR

Fuel Gas Supply System (FGSS)

Langh Tech is the European representative of Korean-based GAS Entec's Fuel Gas Supply Systems. The system is of high quality and reliable design, as GAS Entec has decades of experience in the industry. The system has flexibility through customization to fit any vessel's needs, and an economical design to minimize the initial cost and operating cost.

The shipyard's design and scope is minimized through supply of saddles for LNG tanks, FGSS room design with dimensioning, equipment arrangement and pipe routing, among others, as well as pre-engineering to support the shipyard's basic design.

The FGSS package includes design engineering service, supply of equipment and materials, installation, tests and commissioning. The system is priced competitively due to lack of superfluousness in the design. The customer is supported throughout the entire project.

Flexible design

Well-experienced engineers from Korea’s major shipbuilders

Battery

The Langh Tech battery system is designed to provide the vessel with reliable electrical power for shore-side operations and to assist in or fully provide propulsion during cast-off — ensuring seamless, efficient, and environmentally conscious manoeuvring. A battery string consists of up to twenty connected battery packs, with the number of strings flexible up to sixteen units per battery room, giving an energy storage capacity of 5 MWh.

The system includes several features to ensure a high safety level, also evident in the IP68-rated protection level. Each battery pack includes a dedicated off-gas duct, safely channelling gases out of the battery space to maintain a non-toxic and non-flammable environment. Fire protection is additionally ensured through early-stage threat detection. Cell-to-cell isolation prevents the spread of thermal runaway, significantly enhancing onboard safety and system resilience.

An integrated liquid cooling feature provides a stable and cozy environment for the cells, which is more accurate and efficient compared to air cooling. LFP chemistry offers superior thermal resistance and eliminates risk of thermal runaway, outperforming both traditional lithium-ion (e.g., NMC) and lead-acid batteries in safety, longevity, and environmental impact.

The system is engineered for easy installation and maintenance with minimized operational disruption. An active balancing software optimizes performance and extends battery life, with constant health check on cell and pack level. In the unlikely event of a pack failure, manual string cut-off will ensure continued operation.

IP68-Rated Protection

LFP Chemistry